News

MICROMOBILITY BATTERY MANAGEMENT TECHNOLOGIES: A STATE OF ART REVIEW

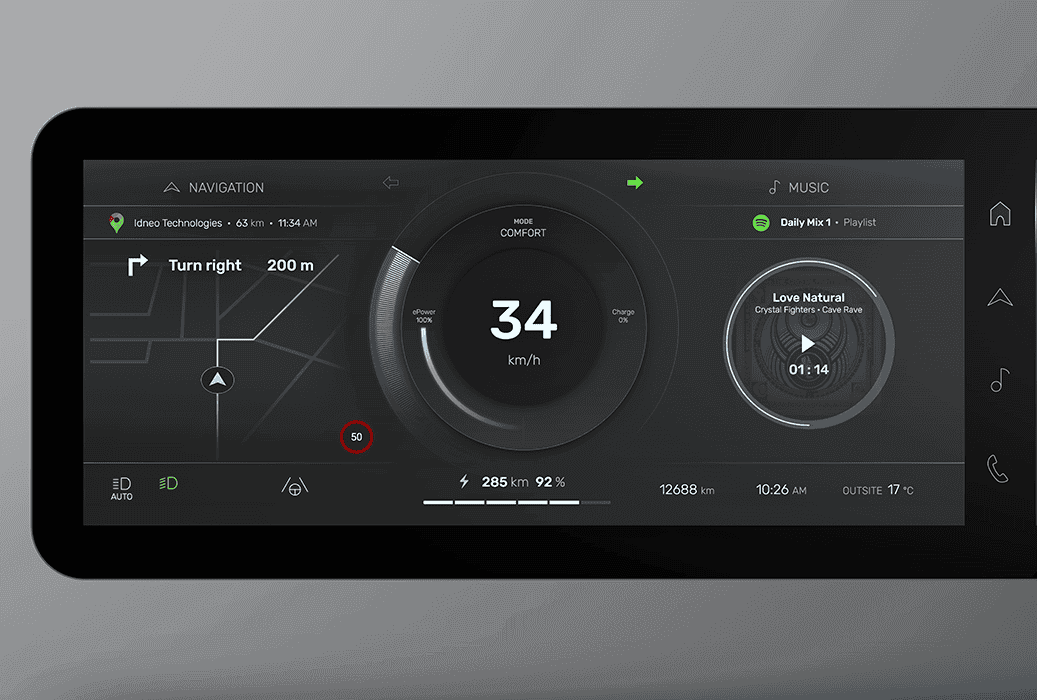

ANTONIO MOLLFULLEDA I Head of Engineering at Idneo Technologies

ENRIC COMAS I BMS design engineer at Idneo Technologies

A key enabler of the micromobility revolution lies in the evolution of battery technologies, which power these vehicles efficiently and sustainably. Every year the world relies increasingly more on battery technology. Electric vehicles went from 10% of global vehicles sales in 2022 and has since reached up to around 30% towards the end of this decade.

Abstract

Micromobility, encompassing various compact, sustainable transportation modes such as electric scooters, bicycles, and small electric vehicles, has gained widespread popularity in urban environments, addressing the challenges of congestion and Pollution. A key enabler of the micromobility revolution lies in the evolution of battery technologies, which power these vehicles efficiently and sustainably. This article provides a comprehensive review of the state of the art of Battery Management Systems (BMS) for non-automotive electric vehicles, including micromobility applications.

The review encompasses a detailed analysis of the latest advancements and BMS functional requirements for next generation lithium-ion batteries, including an analysis of architectures and trends to increase the battery safety mechanisms and, intelligent energy management for prolonging battery life. The first consequence is the change of the models entered in the BMS that allow the real-time diagnostics of the battery. This opens the need of a review of the actual models applied inside the BMS and the possible novel approaches that may be included as the new electric representation of the batteries. Finally, the need of acquiring completely new parameters of a battery may lead into new parameters or sensing techniques that may be included in the BMS. The review also addresses the role of policy frameworks and industry standards in shaping the future landscape of micromobility batteries. By synthesizing the latest research findings and technological breakthroughs, this article offers valuable insights for researchers, engineers, and policymakers, guiding the development of advanced batteries that will power the next generation of sustainable micromobility solutions.

Introduction

Micromobility, encompassing various compact, sustainable transportation modes such as electric scooters, bicycles, and small electric vehicles, has gained widespread popularity in urban environments, addressing the challenges of congestion and pollution. A key enabler of the micromobility revolution lies in the evolution of battery technologies, which power these vehicles efficiently and sustainably. Every year the world relies increasingly more on battery technology. Electric vehicles went from 10% of global vehicles sales in 2022 and has since reached up to around 30% t owards the end of this decade.

Batteries map for EV

For Electrical Vehicles, Lithium Ion Battery (LIB) cells have been widely used, thanks to their intrinsic superiority in terms of specific energy density (Wh/Kg) and volumetric energy density (Wh/L). A LIB is composed of three major parts, the anode, the cathode, and the electrolyte (Lithium salt dissolved in a mixture of organic carbonates) including the separator. The anode is typically composed of graphite, while the cathode might change from different battery types.

The most common cathode for micromobility applications is based on Nickel Manganese Cobalt (NMC). All electrochemical innovations are mainly focused on one or more of these parts. The energy density and cost can be further improved by increasing the nickel content in the cathode. Currently, the so called NMC811 (with an 8:1:1 ratio) can be considered as the state-of-the-art materials for automotive applications providing a specific energy density around 200-250 Wh/Kg. Another popular cathode material is Lithium Iron Phosphate (LFP) which, despite a lower energy density (ranging from 90 to 120 Wh/Kg) benefits from higher safety and longer lifetime.

While LIB cells provide high specific energy density compared to other battery types, they also come with several potential hazards, such as fire or explosion. One of the most common causes of those hazards is the Thermal Runaway (TR). This is a sequence of internal exothermic reactions that lead to an uncontrolled rise in temperature that usually ends in flames or in some circumstances, explosion.

In relation to the next generation in the field of battery chemistries it is worth mentioning:

- Sodium Batteries are becoming a viable alternative to Lithium in some micromobility applications such as e-Bikes or scooters. The internal battery architecture is the same as the LIB with liquid electrolyte, however instead of Lithium, they rely on Sodium (Na). Some small vehicles have already been commercialized with Na Batteries (NAB), but it is still not clear whether these batteries will be competitive in terms of EV autonomy and charging time.

- Solid-State batteries which replace the liquid with ceramic or other solid materials allowing higher energy density, that is, higher energy into a smaller space. Therefore, because some solvents in electrolytes can be flammable causing thermal runaway, the solid-state alternative provides safety improvement by reducing fire risk.

- Self-healing batteries. Following solid-state, self-healing batteries are subject to current research by adding additional sensors and actuators inside the cell. They essentially use polymers (composed of Hydrocarbure chains) as the separator material inside the cell combined with embedded sensors and actuators to detect and recover cracks in the structure of the cell. The recovery methods are based in the application of moderate quantities of heat.

Battery Management Systems

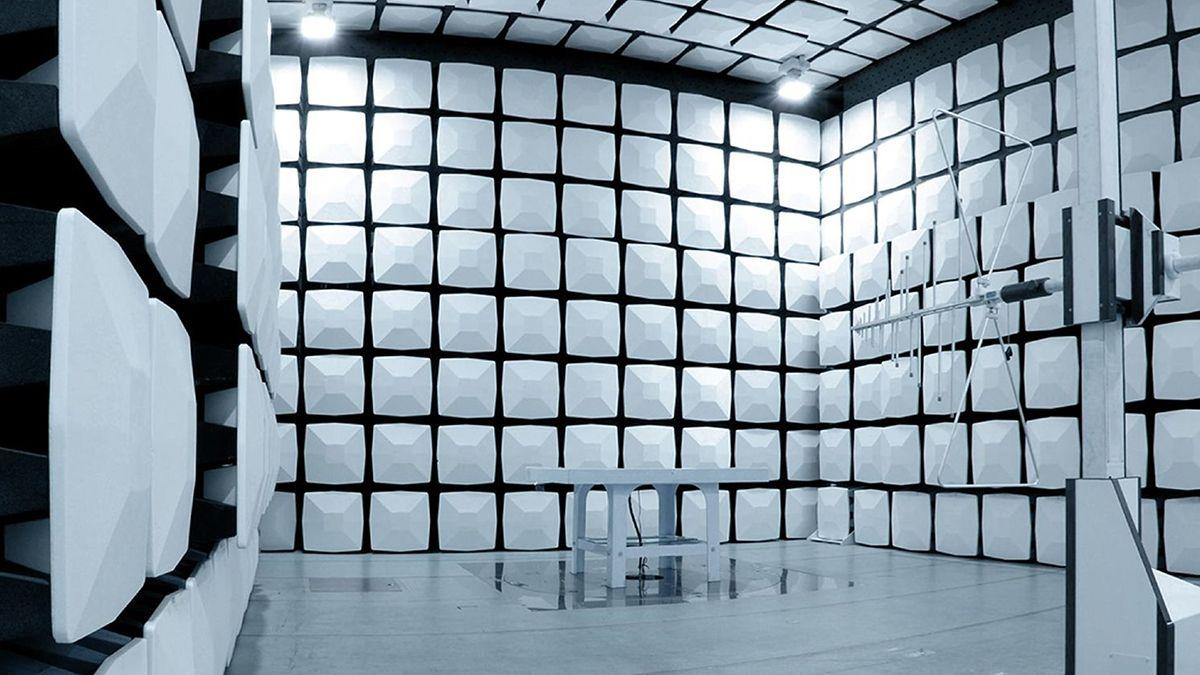

On the top of batteries, the Battery Management System (BMS) is crucial to guarantee the reliable and safe operation of EV batteries by avoiding thermal runaway, protecting against potential short-circuits, over-charge and over discharge. To accomplish this, the BMS must estimate the internal electrochemical state of individual battery cells based on external sensor observations of primary cell parameters such as Voltage, Current and Temperature. Advanced battery management also monitors and process other ancillary data to improve the performance of the battery system. Electrochemical Impedance Spectroscopy (EIS) has been proven to be a reliable indicator of the internal battery state and is being integrated in some modern BMS. Some of those other parameters can be acceleration (used for crash detection), pressure (used to anticipate fire or explosion by detecting initial outgas of the cells) or magnetic fields which is subject of a current investigation since it provides information about the internal electrical behaviour of the cell.

The main functionality of the BMS is assembled in three interactive areas: Primary data management, State Estimation and Actuation.

Primary Data Management

The main functionality of the data management is to organize the data acquisition of the primary data from battery sensors. Given that the BMS is a Safety critical component of the EV and following recommendation from the automotive Safety standard ISO-26262, the first level of data processing is to check the integrity and validity to avoid lack of safety condition due to wrong data. It is followed by a second layer to check that all data is stored in the so-called Safe Operation Area (SoA) of the battery cell. When the data integrity or the SoA cannot be kept in the safe operational range, the BMS activates the Safety protection mechanisms to stop the battery operation.

State Estimation

This is one of the most complex parts of battery management since the internal electrochemical state is unknown and must be estimated from external battery observations. The calculation uses primary data (voltage, current and temperature) in conjunction with a digital battery model.

An accurate digital model of the battery cell is one of the most complex trade-offs in the deployment of a BMS. While simple models allow a low-cost implementation, their lack of accuracy leads to low performance and required additional battery maintenance. The battery modelling techniques can be organized in three main groups:

- Electrical Circuit Model

- Physical electrochemical models

- Data driven models

The most common model is the so-called Electrical Circuit Model (ECM) that characterizes the cell with a low complex electrical circuit lumped element. This approach can provide relatively good performance implemented in low-cost electronics but requires accurate battery characterization of each lumped element at several temperatures and state of charge.

Finally, data-driven models use the abundance of battery available data to develop machine learning models that represent the behaviour and characteristics of the batteries. Data-driven models are superior in performance compared to the others, especially considering the temperature and ageing effects. However, this approach can be easily influenced by the selection of training datasets and the intelligent algorithms. Their implementation is currently out of the capabilities of current low-cost technology; however, they are a promising solution to be implemented in the Cloud as a digital twin of the battery.

Based on the digital model, the most relevant parameters for a proper EV battery management are:

- The State of Charge (SoC) estimation determines how much energy remains in the battery. Its importance relies not only on relevant information for the end user, but also to avoid safety hazards due to overcharge or Deep discharge caused by lack of wrong SoC estimation. The algorithm for SoC highly depends on the digital battery model considered in the BMS. The simplest algorithm is based on current integration in conjunction with look-up-tables that relate the Open Circuit Voltage (OCV) to the SoC. Slightly more complex algorithms are based on ECM and use statistical filters to correlate the measurement of primary data with the model outputs to find the state that minimizes the error between both datasets. The most complex and intelligent algorithms are based on Machine Learning approach, providing reliable performance as long as training dataset.

- Stage of Health monitors the internal state helps to estimate the maximum capacity of the battery. It is normally defined as the available battery capacity in relation to the nominal capacity.

- The State of Safety (SoS) is one of the most innovative parameters managed by advanced BMS that is still a subject of investigation. Experience from the last 10 years of the deployment of EVs resulted in some unexpected fires. Around 25% of EV fires occurred when the battery was inactive (neither charging nor discharging). This fact motivates the estimation of the State of Safety with the objective of anticipating the unexpected fires in advance to allow proper maintenance of the battery. This parameter measures the accumulation of the thermal, mechanical, and electrical stress suffered by the battery during its lifetime. Subsequently, the SoS estimates the probability of unexpected fire.

Actuation and Control

The actuation and control part of the BMS interacts with the rest of the battery ecosystem, even internal cells, or external elements (such as main contractor or thermal control), to protect against a potential hazard and to optimize the whole performance of the battery. Several functions are included in this area:

- Cell Balancing. Battery cells in pack may have distinctive characteristics such as different capacity of different internal resistance. This is due to variances in the manufacturing process, or to different stress suffered by the cell. In any case, the BMS needs to monitor the voltage of each cell and ensure that they are all equilibrated by burning with additional current those cells with higher voltage (passive balancing).

- Protection against operation out of the Safe Operation Area. Individual cell monitoring allows the BMS to detect internal short-circuits, as well as other potentially dangerous situations such as over voltage, under voltage, over temperature, under temperature, overcharge or over discharge conditions.

- Thermal Control. Based on the battery cell temperature external temperature control mechanism is activated to maintain the temperature at the optimal performance level. Normally temperature control is used to maintain temperature at optimum performance, at low ambient temperature. Modern and advanced batteries include active cooling mechanisms.

- Self-healing. Future battery cells under current investigation include healing mechanisms to repair internal chemical structure of the cell. By activating a controlled heating mechanism at some points of the cell the polymer tends to recover its original state causing healing effect under damaged conditions.

Conclusions and Future trends

Summarizing, battery Management ensures the safe and efficient energy source of an electric vehicle through the measurement of several primary data from battery cells such as voltage, current and temperature. From this data, the estimation and calculation of the internal state of the battery is based on a digital model and algorithms. Among the future trends for the next generation of BMS expecting an enhancement of the battery safety and performance it is worth mentioning as the main promising technologies:

- Additional sensors such as EIS sensor, pressure sensor (to anticipate and stop Thermal runaway) or magnetic sensors (as an indicator of the internal electric behaviour).

- Artificial intelligence to improve battery state estimation.

- Integrated Self-healing batteries.