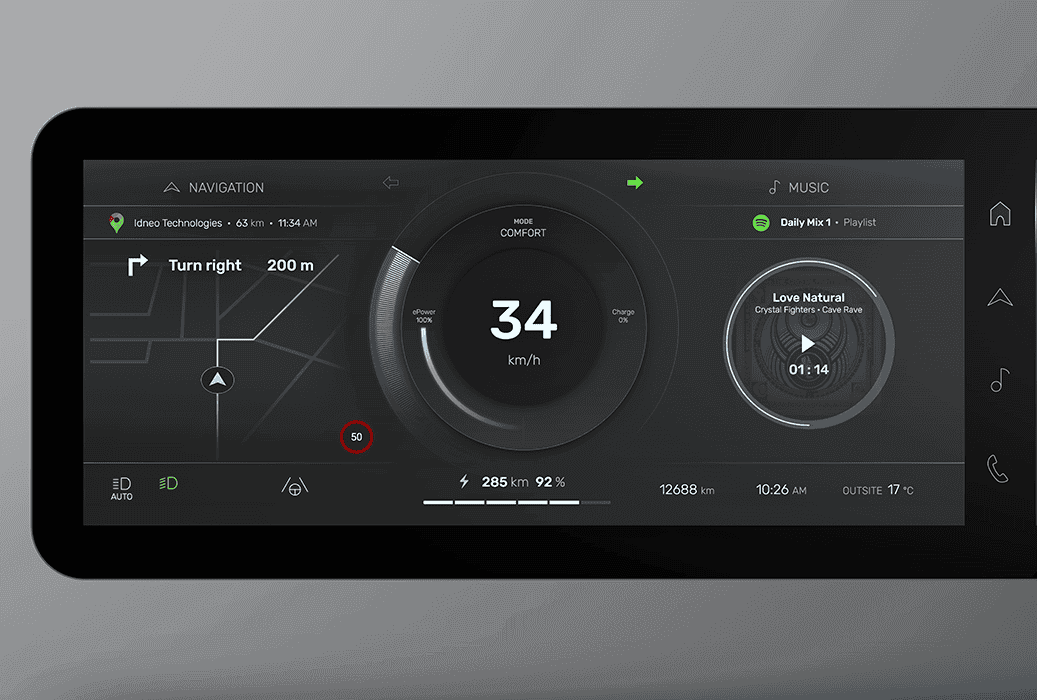

ENGINEERING THE FUTURE

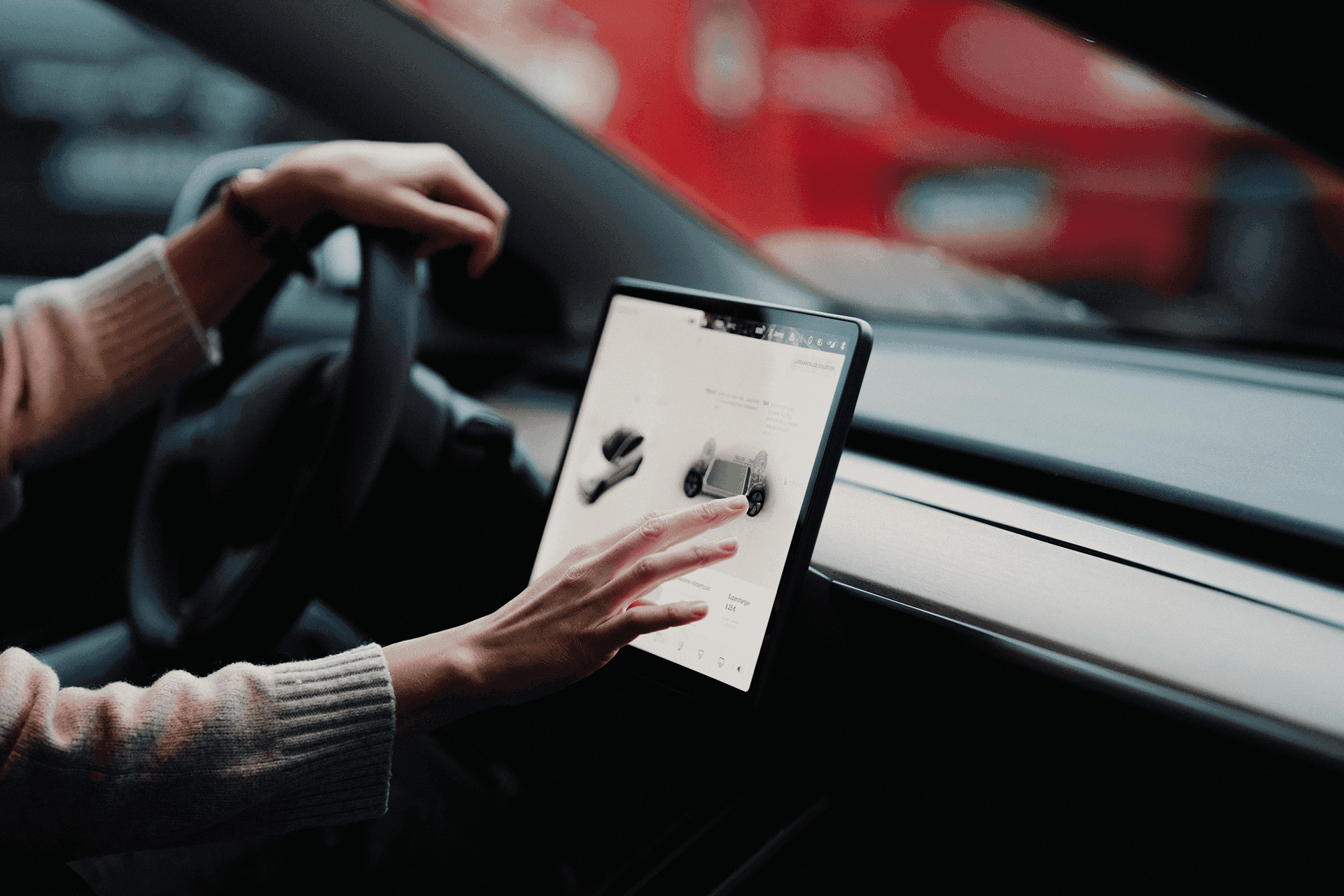

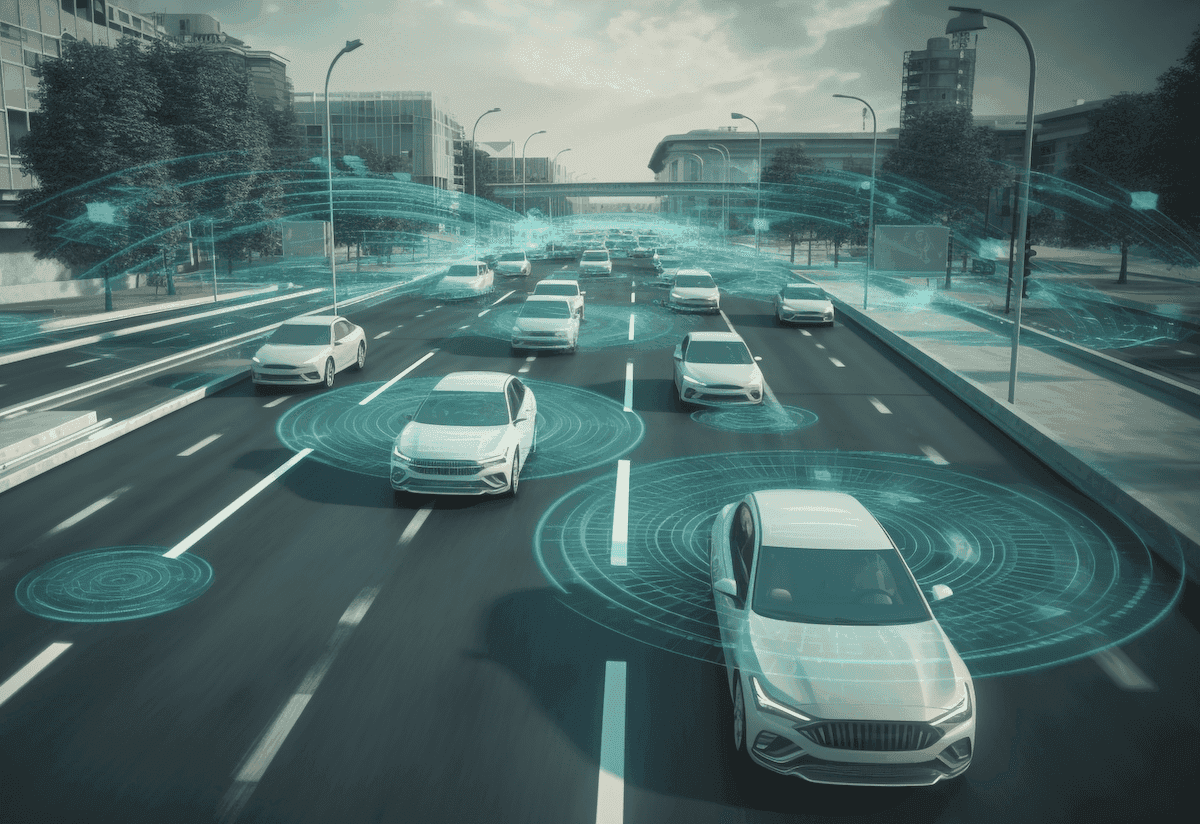

we make real products with real impact

ONE STOP PARTNER

from the idea to the manufacturing and support

JOIN OUR team

JOIN OUR team

Are you ready to take your career to new heights? At Idneo we are on a mission to innovate, create, and push boundaries of what's possible. We are looking for excepcional people like you to join us on this exciting journey.