SmartBMS

Industrial BMS for 16 Cells

Home

/

ventures

/

battery management system

/

SmartBMS Industrial

Industrial BMS for 16 Cells

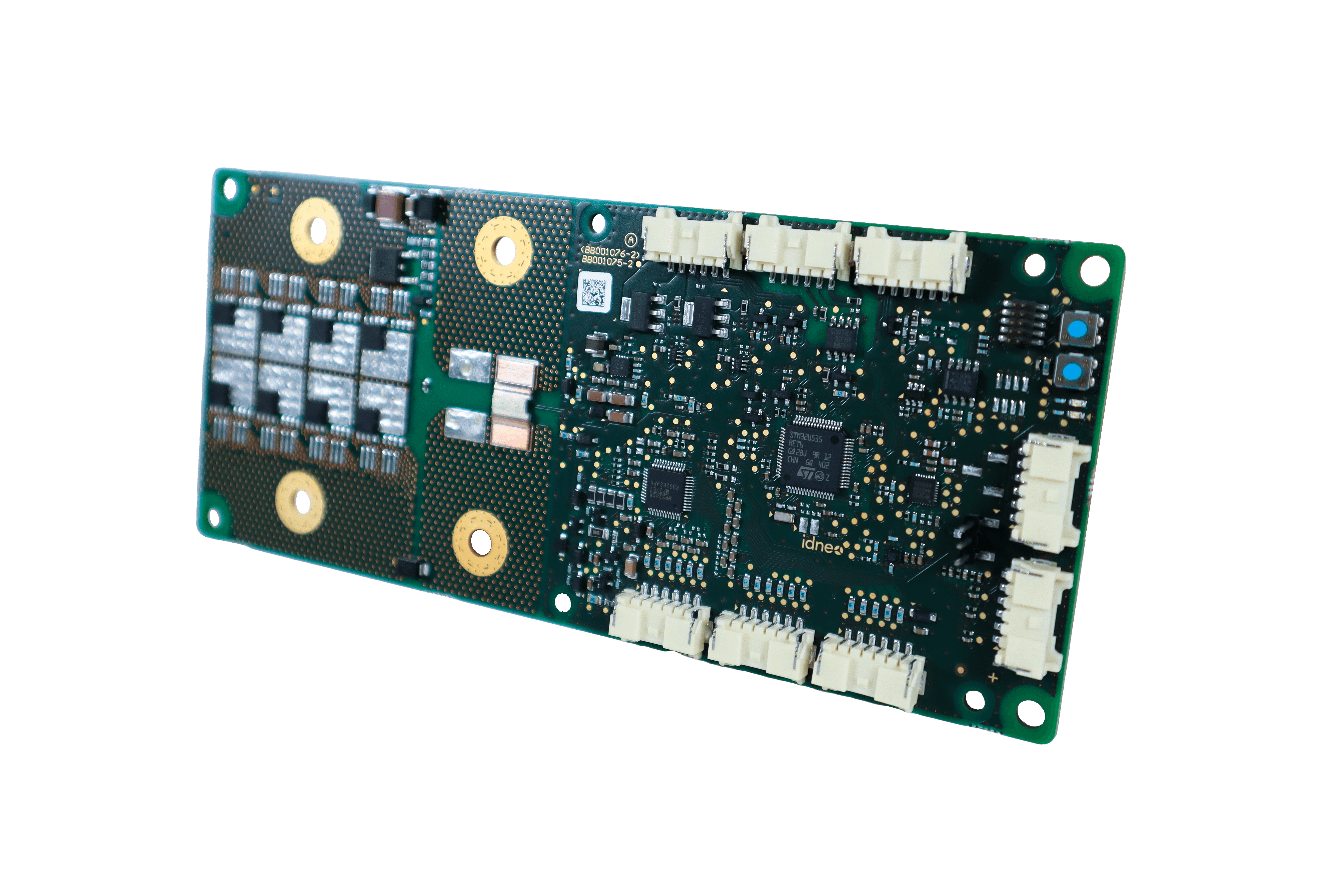

Idneo’s SmartBMS is an industrial centralized BMS system that can manage the control of a maximum of 16 battery cells of different chemistries and includes in the PCB configurable distribution of MOSFET switch and shunt current measurement.

It allows regenerative power management as well as thermal management through heater control. With passive cell balancing and pre-charge functionality.

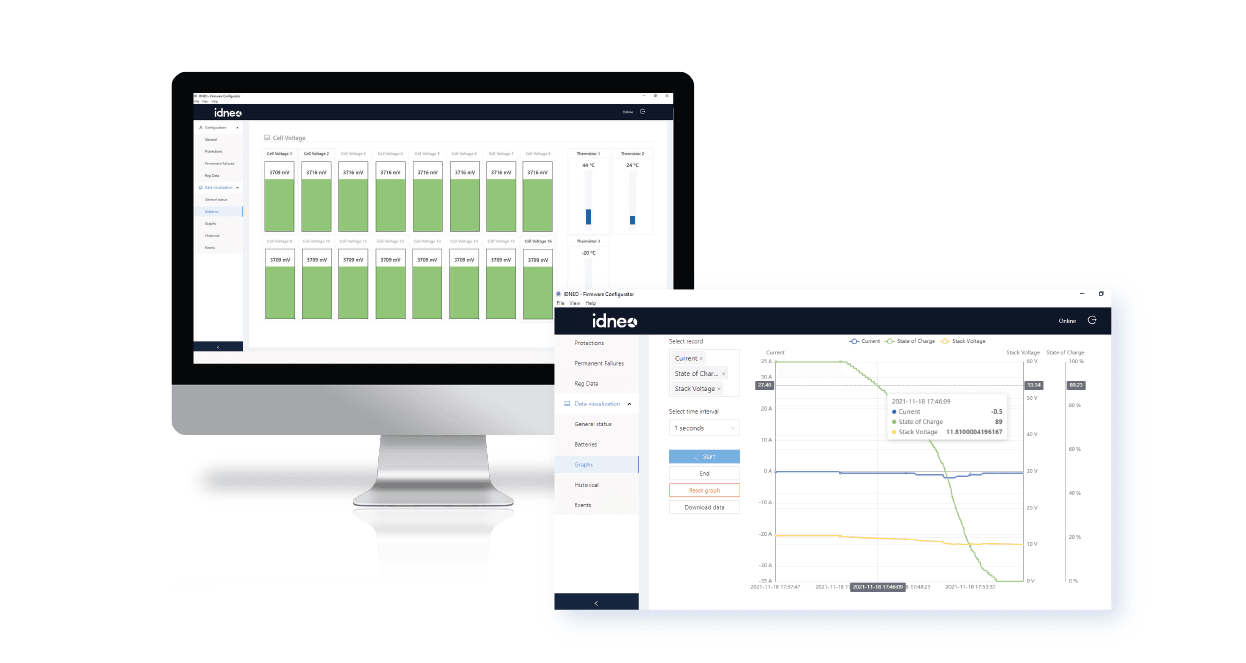

Integrated configurable Fuel Gauge for SoC, SoH, Instantaneous Available Power, Remaining Runtime and Charge Time.

APPLICATIONS

- AGV (Automated Guided vehicles)

- Advanced stationary battery

KEY FEATURES

- Cost Effective solution based on Configurable Internal Electronic switch

- Configurable voltage temperature and current protections

- Supports a Wide Variety of Lithium Cells

- Cell Profile Database Updates for the Fuel Gauge

- Characterization of custom cells on demand

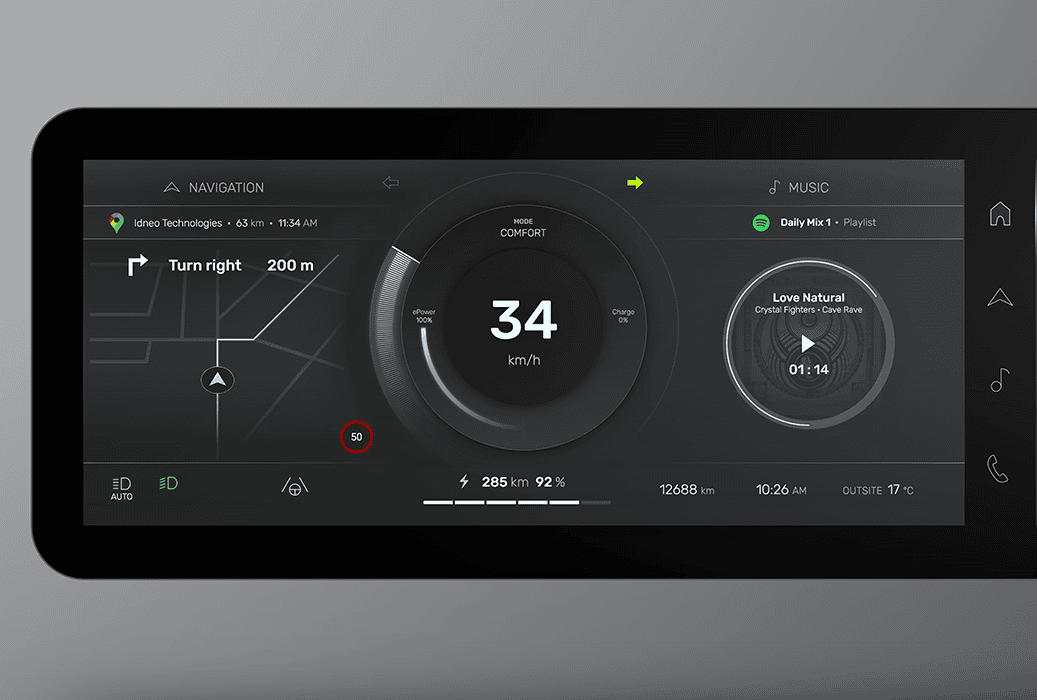

- Visualization of voltages and temperatures for each cell

SPECIFICATIONS

| Size | 74 x 174 mm |

| Voltage Resolution | < 5 mV |

| Temperature resolution | < 2 ºC |

| Current Resolution | < +-0,5 % |

| Temperature readings | Up to 6 NTC Measurement 1 internal PCB measurement |

| Current Measurement | Internal PCB shunt-configurable |

| Power output / charger switch | Cost Effective solution based on Configurable Internal Electronic switch depending on current demand: 15 A, 35 A, 75 A, 150 A Pre-Charge circuit up to 1A |

| Voltage Range | 18 to 75 V |

| Communication | CAN - UART for debug |

| Min Number of Cells | 7 |

| Max Number of Cells | 16 |

| Cell Voltage range | 1V to 5V |

| Cell Balancing | Up to 58mA per cell |

Fuel Gauge SoX Calculations | Pack and Cell SOC Pack and Cell SOH Remaining Runtime and Charge Time Instantaneous Available Power For wide variety of Lithium cells |

| Operating Temperature | -30ºC to +65ºC |

| Storage Temperature | -40ºC to +80ºC |

| Weight | ~32g |

| Connectors | 8 x JST SM06B-PASS

1 x IDC 2,54mm -Uart debug |

ARCHITECTURE

OPEN BMS | |||

DIAGNOSTICS |

DATA MANAGEMENT |

FREE RTOS | Custom Application SW: Custom SoX Algorithms, Battery Stateme Machine, Charging Profiles, Custom Communications (CAN DBc) |

| L2: Safe Operating Area (SoA) Fuel Gauge SoX | |||

| L1: Acquisition & Diagnostics | |||

| L0: Low level Libraries & Drivers | |||